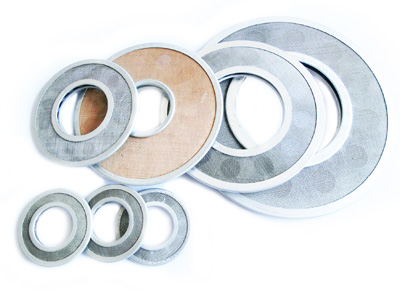

Conical Strainers: Efficient Temporary Filtration Solutions for Coolants and Cutting Oils

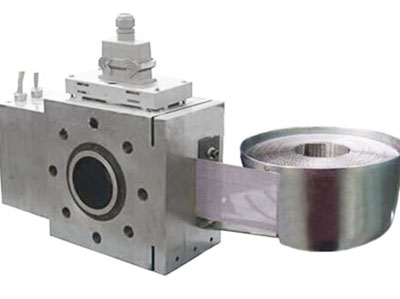

Conical strainers, also known as temporary filters, are widely used in industrial fluid systems to remove solid contaminants from liquids such as coolants and cutting oils. These filters are typically installed during system start-up, commissioning, or maintenance to prevent debris and suspended solids from entering downstream equipment.

By effectively capturing metal chips, machining debris, and other particulate contaminants, conical strainers help maintain fluid cleanliness, protect pumps and machine components, and ensure stable and reliable system operation. Clean coolant and cutting oil also contribute to improved machining quality and extended equipment service life.

Filtration Performance in Different Applications

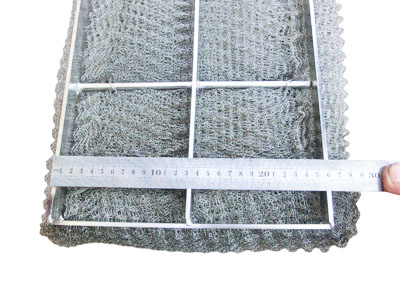

Coolant Filtration

Coolants used in machining and metal processing often contain metal chips, fines, and residues. Conical strainers effectively remove these contaminants during circulation, protecting machine tools, maintaining coolant stability, and supporting consistent cooling performance.

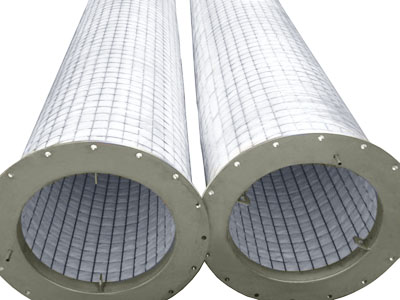

Cutting Oil Filtration

Cutting oils play a vital role in lubrication, cooling, and chip removal during metalworking operations. Over time, these oils can accumulate metal particles, oil degradation products, and other contaminants. Temporary conical strainers efficiently remove these impurities, improving oil cleanliness, extending oil service life, and enhancing overall machining performance.