Stainless Steel Mesh Filter Material Buying Guide

1. Choosing Stainless Steel Mesh

Material

Use stainless steel that resists rust and corrosion well, like 304 stainless steel or 316 stainless steel.

304 stainless steel is good for normal conditions.

316 stainless steel is better for harsh or corrosive environments.

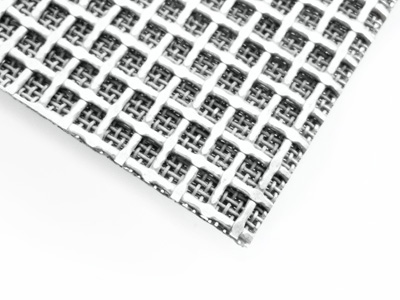

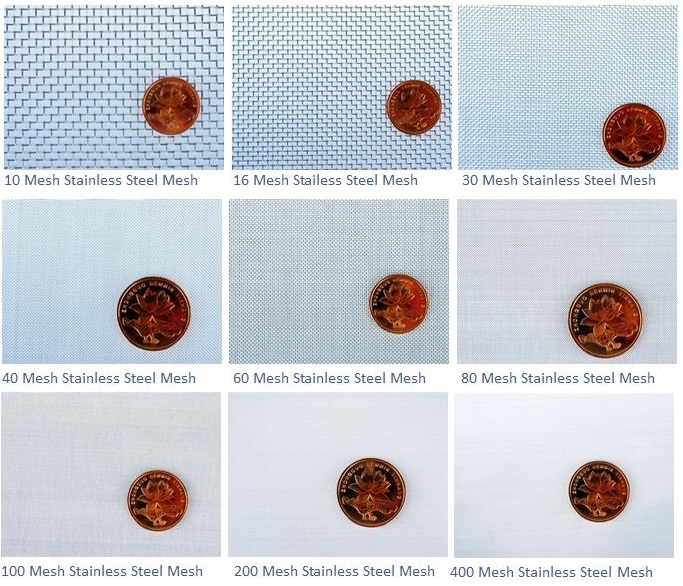

Mesh Size (number of holes):

Choose mesh from 20 to 500 mesh, depending on how fine the filtering needs to be.

Higher mesh numbers = finer filtering, but water or air may pass through more slowly.

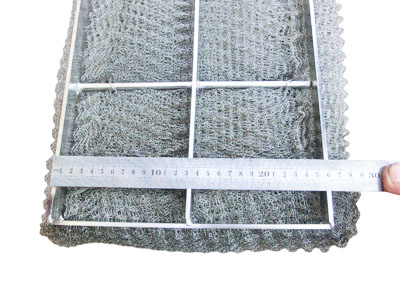

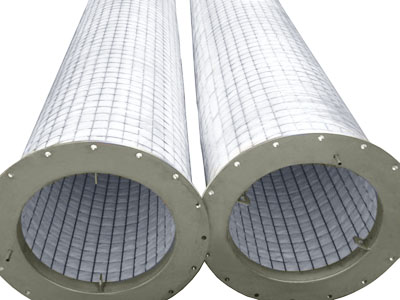

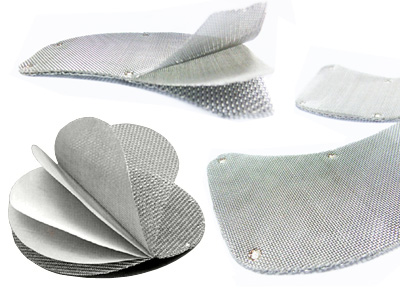

2. Choosing the Support Mesh

Purpose:

Support mesh helps keep the filter strong and in shape during use. It stops the mesh from bending or breaking.

Tips:

Choose the right support mesh based on your working environment and pressure.

Common materials: stainless steel

Support mesh usually has lower mesh numbers (bigger holes) than the filter mesh to stay strong.

3. Other Supporting Materials

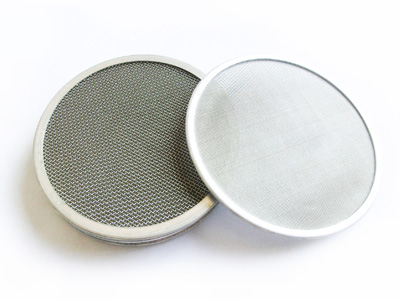

Edge Material:

To make the filter safer and longer-lasting, add a metal frame or edge.

Use the same material as the mesh: 304 or 316 stainless steel.

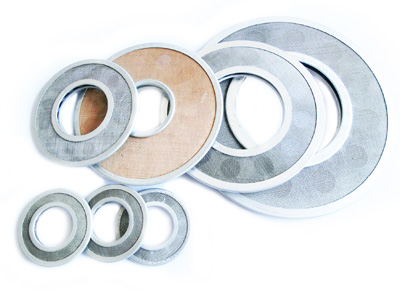

Welding Material:

Use welding materials that match the mesh and support mesh.

This keeps the welds strong and rust-free.

Common welding methods: spot welding, seam welding, the method depends on the size and design of your filter.

By choosing the right materials, you can make your stainless steel mesh filter work better and last longer.