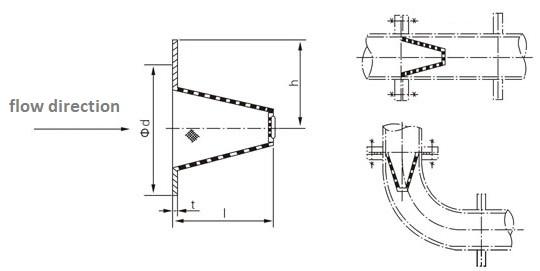

Temporary Conical Strainer Usage and Installation Guide

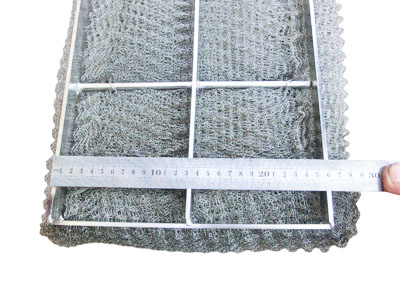

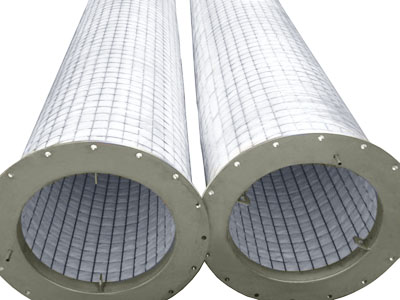

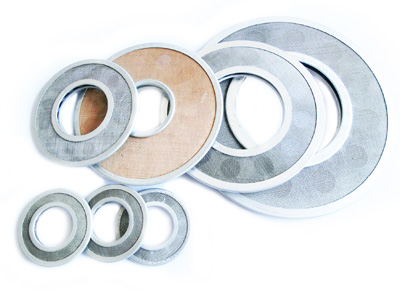

The temporary conical strainers is a type of coarse pipeline filter designed to remove impurities from the medium within the pipeline. It ensures proper equipment operation and guarantees safe production.

When the fluid enters the filter, the impurities in the pipe are blocked by mesh, and the clean fluid flows out from the other end. When cleaning is required, the conical strainer needs to be removed from the pipeline, cleaned and then reinstalled.

Installation Guide

1. Verify Fluid Medium Temperature and Pressure:

Ensure the temporary conical strainer can withstand the actual temperature and pressure difference to avoid damage caused by high temperatures or pressure, which could harm downstream equipment.

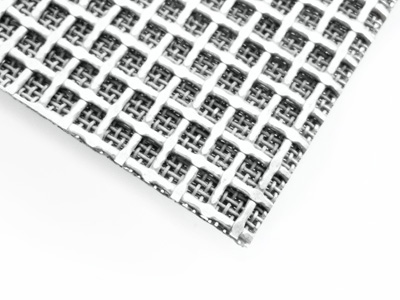

2. Choose an Appropriate Filtration Precision:

The mesh aperture should be slightly smaller than the size of the expected impurities.

If the aperture is too small, it may create a significant pressure drop, leading to filter failure.

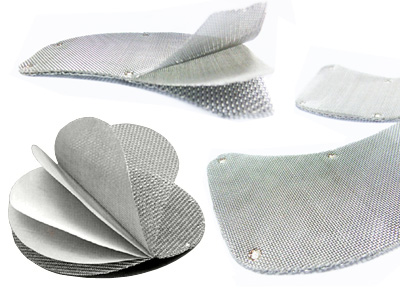

3. Consider Ease of Assembly and Disassembly:

Install pipe supports or hangers near the temporary conical strainer for convenient assembly and disassembly.

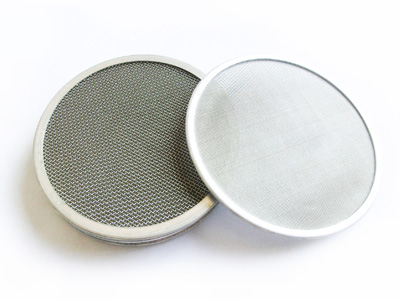

4. Facilitate Conical Strainer Replacement:

Prepare a spare conical strainer to use when replacing the old one.

Install shut-off valves such as gate valves at the replacement position to isolate upstream and downstream fluid, making replacement easier.

5. Select an Appropriate Installation Location:

Avoid installing the temporary conical strainer directly upstream of flow-sensitive equipment.

Whenever possible, place it in a downstream position to minimize impact on flow dynamics.